Skimmed Milk Powder is a dairy product made by evaporating fresh pasteurized skimmed cow’s milk or from collected cream. There are three main classifications: High-heat (least soluble), Medium-heat and Low-heat (most soluble).

Dried Milk is used primarily as a food ingredient. It may be used in products like: Baked goods, confections, ice creams, frozen dairy products and sweets, cheese analogues, sports and nutrition foods, etc. Proteins: no less than 34%; Fat: no more than 1,25%; Ash: no more than 8,5% SMP is available in packs of 25kg, „Big Bag” 500-1000kg, or wholesale.

Average Shelf life of SMP is about 12 months.

Range

- Low heat

- Medium Heat

- High Heat

- Organic

Instant or regular – with or without lecithin

Applications

- Recombined dairy products (UHT milk, yoghurts, cheeses…)

- Bakery (as non-fat milk solids)

- Chocolate – Confectionery

- Ice cream

Skimmed milk powders are manufactured thank to a very simple process. They are obtained from fresh cow milk that has been skimmed, pasteurised and concentrated by vacuum evaporation. This concentrated milk is then spray dried or roller dried.

The temperature at which the concentration happens indicates the characteristics of the 0% fat milk powder: Low Heat, Medium Heat and High Heat.

Skimmed milk powder is used as an alternative to fresh milk after dissolution in water or by direct addition of the powder in the formulation, for instance to standardise dry extract content or protein content.

Lecithin may also be added at the end of the drying session to obtain spray instant skimmed milk powder. Lecithin is used for its emulsifier properties that helps the powder rehydrate quickly.

Skimmed milk powder is mostly used in products based on reconstituted milk (yogurt, dairy dessert, ice creams…), in chocolates, in confectionery, in baby food, in animal feeding.

Possible uses for skimmed milk powder and their advantages are:

- Dairy produce: Alternative to the drinking milk,

- Confectionery:

- Puffed confectionery (malted milk, nougat):

- Stabilisation of the foam and prevention of bubble collapse,

- Light taste of milk,

- Firm texture for chewing: saccharose crystallisation control (thanks to its lactose content) and retention of water.

- Caramel confectionery:

- Crucial to obtain the right colour: Maillard reaction.

- Milk chocolate:

- Distinctive taste,

- Smooth and milky texture.

- Soft candy and coating.

- Bakery:

- Breads, cakes, rolls:

- Nutritional value,

- Taste enhancement,

- Browning increase,

- Improvement of water retention capacity,

- Freshness extension.

- Ice creams:

- Important source of non-fat solids,

- Regulation of the protein vs fat rate,

- Ice cream stabilisation.

Milk powders are solid ingredients obtained through a dehydration process, also called milk drying. The final water content shall not exceed 5% of the total weight.

This almost total dehydration allows milk powder to be stored at room temperature. However, it is sensitive to heat and humidity. It must be used or consumed immediately after being reconstituted by adding liquid.

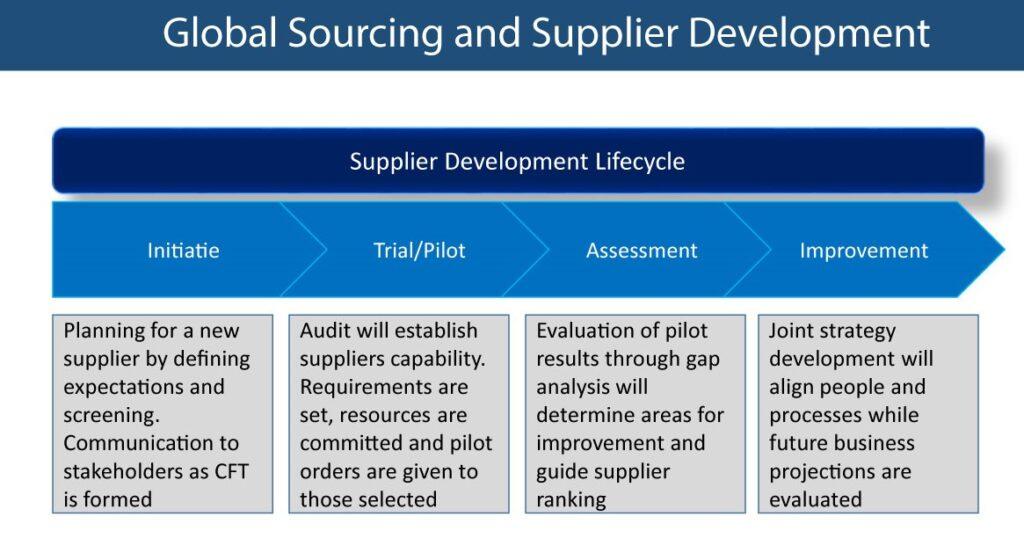

After milking, the milk is collected and refrigerated. The quality of the milk is analyzed several times during its transportation to the storage dairy (before and after collection, as well as after unloading at the dairy).

The product is then standardized. The standardization (skimming of the milk and proportioning of the cream) makes it possible initially to separate the milk and the cream, then to adjust the level of fat of the product by adding more or less cream to it.

The next step is pasteurization. The milk is heated to 71-72°C for 15 to 40 seconds. This heat treatment eliminates microorganisms that are pathogenic for humans.

Concentration by vacuum evaporation consists in eliminating water by boiling (the steam is used as a heat transfer fluid and gives its heat to the component to be evaporated).

Concentration by ESV meets technical and economic issues, as well as quality criteria.

The physicochemical characteristics of the concentrate – which determine the quality and properties of the powders – depend on the time/temperature relationship and the concentration level of the electrolytes.

Two types of drying are used:

- Spray drying: milk is vaporised as droplets in a drying room (warm and dry atmosphere) and is collected as powder. It is referred to as spray milk powder.

- Roller drying: milk travels outside two rotating rollers that are heated from the inside and is collected as flakes. It is referred to as roller milk powder.

Finally, the powders are packaged before marketing.

The quality of the product before drying and the process used are among the factors that have an impact on the properties of the final powder.

The so-called “general” properties of milk powders depend in particular on the quality of the initial product and the technologies used for their manufacture:

- Biochemical and physico-chemical properties: relating to protein, lactose, minerals, fat, free and bound water content, water activity and glass transition

- Microbiological qualities

- Organoleptic properties

The so-called functional and usage properties of milk powders depend mainly on the drying process used:

- Hydration

- solubility (ability of a substance to dissolve in a liquid)

- dispersibility (ability of aggregates to distribute uniformly in contact with water when hydrated. In the case of a powder, we look for the instantaneous character of its dispersibility)

- wettability (ability of a powder to hydrate according to its affinity for water)

- Granulometry

- Mass density

- Flow – Slump

- Friability

- Hygroscopicity

- Caking (formation of small aggregates of powders when the product is exposed to high temperatures or absorbs moisture. The caking can lead to the mass setting of the powders)

- Thermoplasticity